© Hyperviant 2026

FWDAnalyser Software

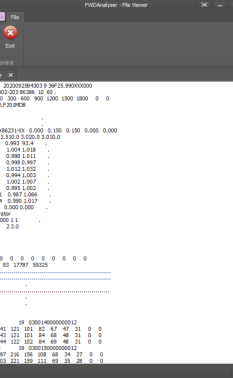

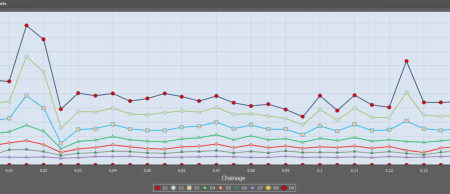

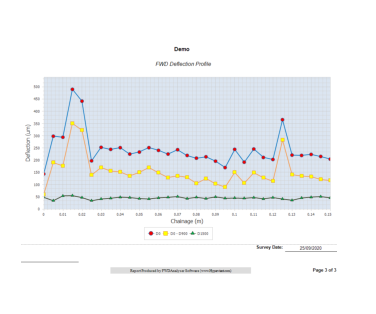

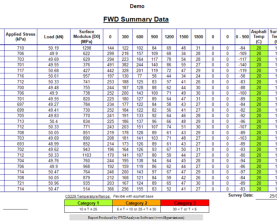

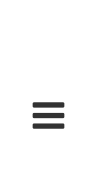

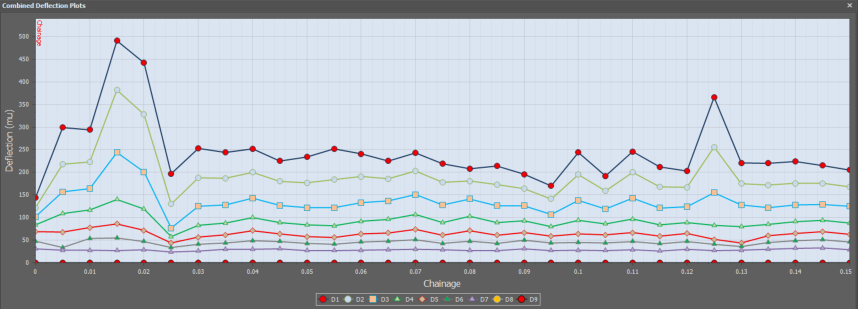

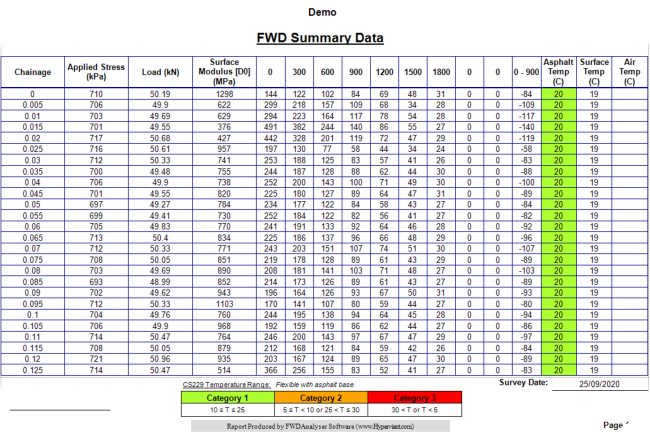

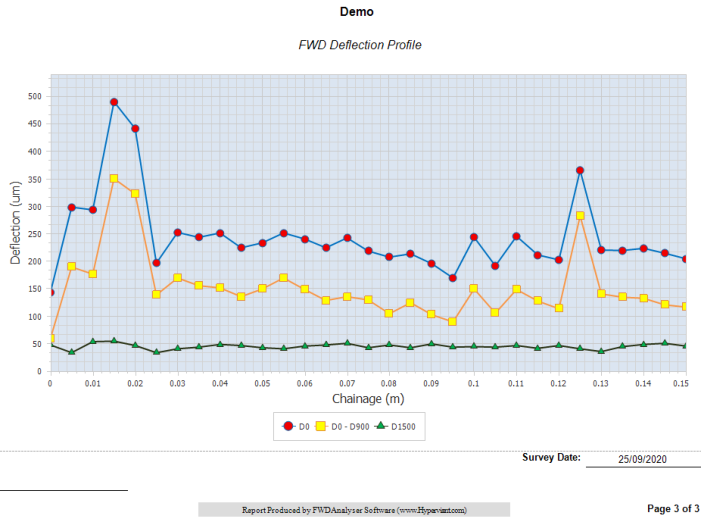

FWDAnalyser software allows users to interrogate F20 files, produced by Falling Weight Deflectometers (FWD). Once the data has been loaded into the software, the user can undertake the following tasks:- • Normalise Data to any Stress or Force value • Produce Deflection Profile plots • Interrogate the deflection bowls • Plot the test positions on maps • Condition format the temperature data to the requirements of CS229 • Stress Dependency Plots • Customise data outputs by switching geophones off • and much more Why not try it out!Falling Weight Deflectometer (FWD)

The Falling Weight Deflectometer (FWD) is a non-destructive testing device used to provide periodic evaluation of the structural capacity and integrity of test sections of a road pavement. The FWD consists of a drop weight mounted on a vertical shaft and housed in a trailer that can be towed by most conventional vehicles. The FWD equipment applies impulse loading to a circular plate in contact with the pavement surface. Usually the load range is 7kN to 150kN, however a Heavy Weight Deflectometer (HWD) can measure up to 350kN. Variation in the applied load levels is achieved by varying the magnitude of the dropping mass and the height of the drop. The applied load level isof an impulse type and is recorded by a load cell. The FWD is used largely because of its ability to impose high-amplitude dynamic loads, like those imposed by Heavy Goods Vehicle (HGV) traffic. The FWD signature is similar to that of a standard (40kN) half axle travelling at typical highway speeds i.e. 50 – 80 km/h. Thus, the measured pavement response is considered a realistic measure of the pavement response to real traffic. The load pulse is approximately that of half sine wave form. The drop weight is hydraulically lifted to predetermined heights ranging from 50-510mm. The weight is usually dropped onto a 300mm diameter loading plate resting on a 5.6 mm thick rubber buffer.

Try out the FWDAnalyser

© Hyperviant 2026

FWDAnalyser Software

FWDAnalyser software allows users to interrogate F20 files, produced by Falling Weight Deflectometers (FWD). Once the data has been loaded into the software, the user can undertake the following tasks:- • Normalise Data to any Stress or Force value • Produce Deflection Profile plots • Interrogate the deflection bowls • Plot the test positions on maps • Condition format the temperature data to the requirements of CS229 • Stress Dependency Plots • Customise data outputs by switching geophones off • and much more Why not try it out!